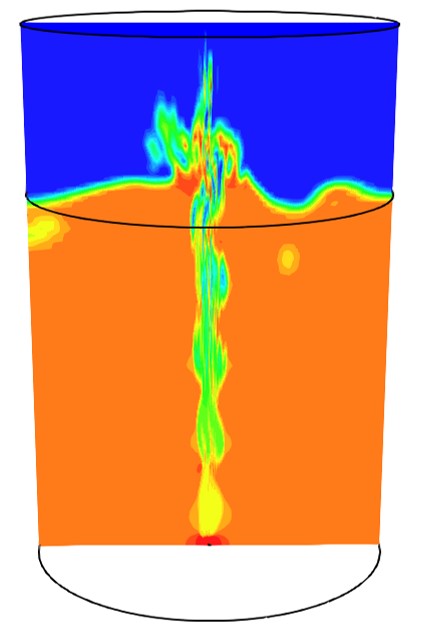

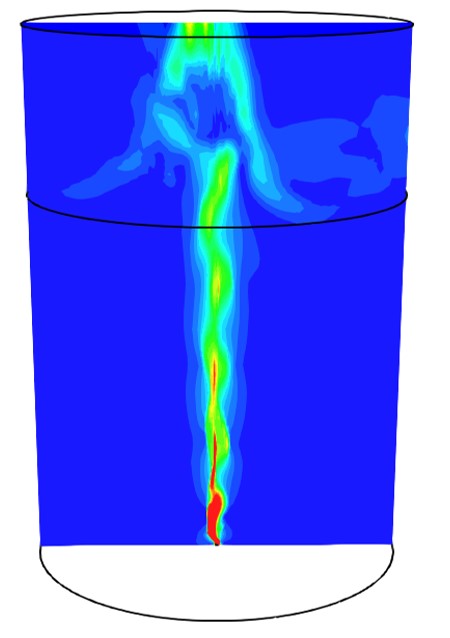

CFD Simulation of a degasser

Gas injection into liquids is an important part of many processes throughout chemical, metallurgical, and water treatment industry. The utilization of Computational Fluid Dynamics (CFD) to analyse gas injection and free surface flows plays a pivotal role to increase the performance in these applications. For instance, bubbles can be introduced into a liquid medium to significantly enhance mixing, or to catalyze chemical reactions.

An industrial example of gas injection into a dense liquid metal melt is the ladle treatment of liquid metals in steelmaking. The animation is representing a simplified setup to illustrate the phenomenon. Argon gas is injected into molten steel to refine it, remove impurities, and improve inclusion cleanliness. This process is essential for producing high-quality steel.

These techniques are widely used in metallurgy to optimize processes and improve product quality.

CFD modeling serves as a powerful tool for simulating these complex phenomena, providing insights and analyses with remarkable accuracy.

- Troubleshooting: One of the key applications of CFD is identifying operational challenges, such as uneven gas distribution, bubble coalescence, and inadequate mixing efficiency. By leveraging insights derived from CFD simulations, engineers can pinpoint specific issues and implement targeted solutions, which may involve adjusting operational parameters or reengineering system designs.

- Design Optimization: CFD also facilitates the advancement of system designs by ensuring efficient gas-liquid interactions and optimal mixing prior to actual construction. This proactive approach not only aims to achieve desired operational outcomes but also takes into consideration spatial limitations and economic constraints, resulting in systems that are both effective and sustainable.

- Performance Prediction: Furthermore, CFD empowers engineers to forecast the behavior of gas injection processes across a spectrum of operating conditions. This predictive capability is essential for determining the maximum efficiency and throughput of the system, ensuring that performance is not compromised while optimizing operational capacities. By simulating various scenarios, CFD assists in fine-tuning processes to achieve peak performance levels.

If you’re interested in exploring CFD’s potential in similar applications, please don’t hesitate to reach out.