CFD Simulation of Spray and Atomization

Spray and atomization processes are essential to numerous industrial applications, including fuel injection in engines, spray drying, and advanced coating technologies. However, conducting experimental studies on these processes presents significant challenges due to their high-speed, turbulent, and multiphase characteristics. This complexity makes it clear that Computational Fluid Dynamics (CFD) is not just beneficial but indispensable for effectively analyzing and optimizing the design and process conditions.

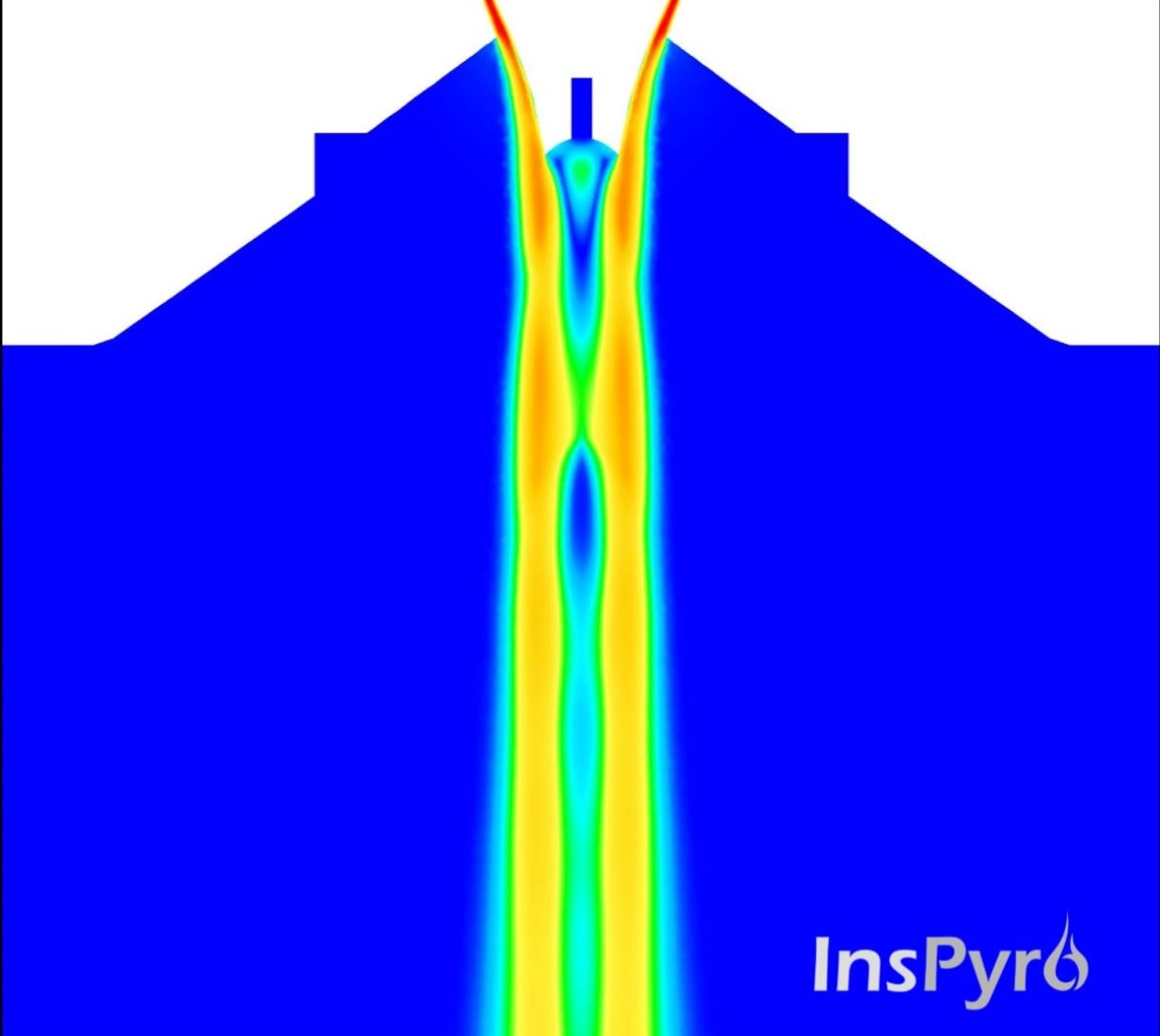

The fluid dynamics of spray formation and atomization are quite complex, as they involve the interplay of turbulent flows, liquid breakup, droplet formation, and evaporation. Simulations demonstrate that accurately modeling these processes is essential for understanding the distribution of the spray, as well as the size and velocity of the droplets. CFD results offer detailed insights into the structure and behavior of the spray under various operating conditions.

Several scenarios can be studied using CFD to optimize spray and atomization processes:

- Droplet Size Distribution: Ensuring that droplets are within the desired size range to improve mixing, combustion efficiency, or coating uniformity.

- Evaporation and Mixing: Studying the evaporation dynamics of liquid droplets and their mixing with the surrounding medium, which is crucial for applications like fuel injection in internal combustion engines.

- Atomization Efficiency: Enhancing nozzle designs to achieve better liquid breakup, reducing energy and gas consumption and ensuring uniform spray patterns.

- Finding a Fitting Nozzle for a Certain Process: Evaluating and comparing different nozzle designs to determine the optimal one for specific process requirements, such as flow rate, spray pattern, or droplet size distribution.

CFD modeling of spray and atomization involves advanced techniques, such as Volume of Fluid (VOF) for liquid-gas interface tracking, or Lagrangian particle tracking (DPM) to simulate individual droplets, or a combination of both (VOF-to-DPM). These simulations provide a powerful way to evaluate nozzle performance, optimize operating conditions, and improve overall process efficiency.

Dynamic simulations can also be performed to analyze transient behaviors, such as the initiation of spray formation or variations in atomization during start-up and shut-down phases. If you’re interested in exploring CFD’s potential in spray-related applications, feel free to reach out!