METSIM®

Flowsheeting in metallurgy and mining

The basis for analysis of all chemical and metallurgical processes is the mass and energy balance. Plant design, capital costs, and technical evaluations are all dependent on such calculations. Why do we like METSIM® so much as a tool:

- Easy to add and remove unit operations

- Large freedom in defining reactions

- Steady state and dynamic flowsheeting is possible

- Fast convergence

- Several predefined unit operations combined with basic mixing and splitting results in a flexible modelling tool

- Gradual learning curve leading to immediate useable results even for less experienced modellers.

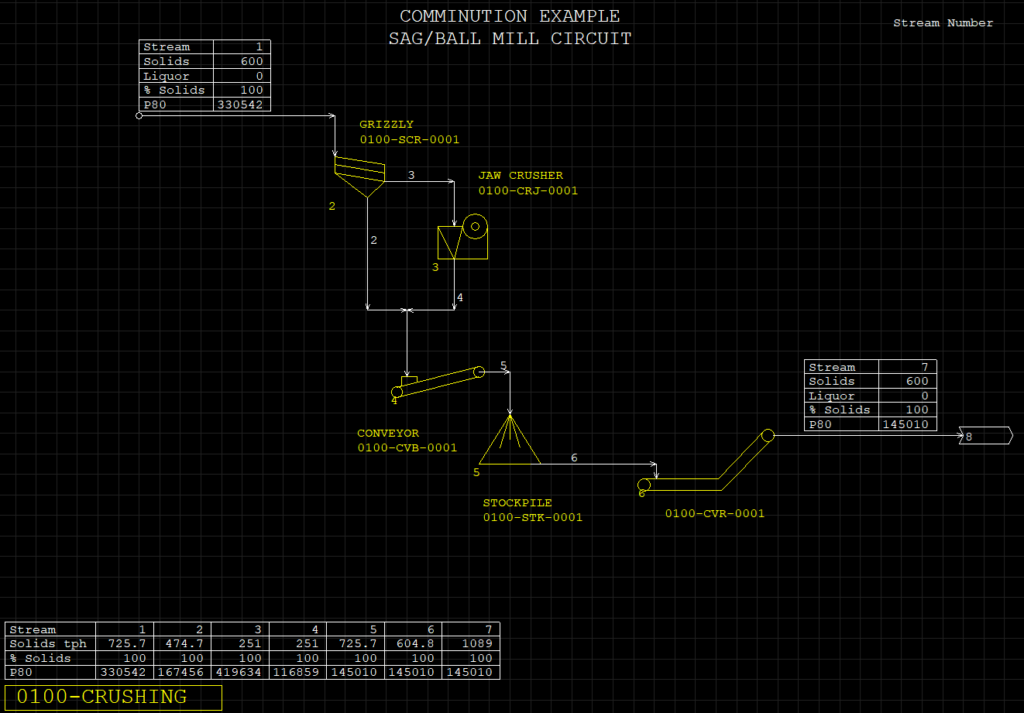

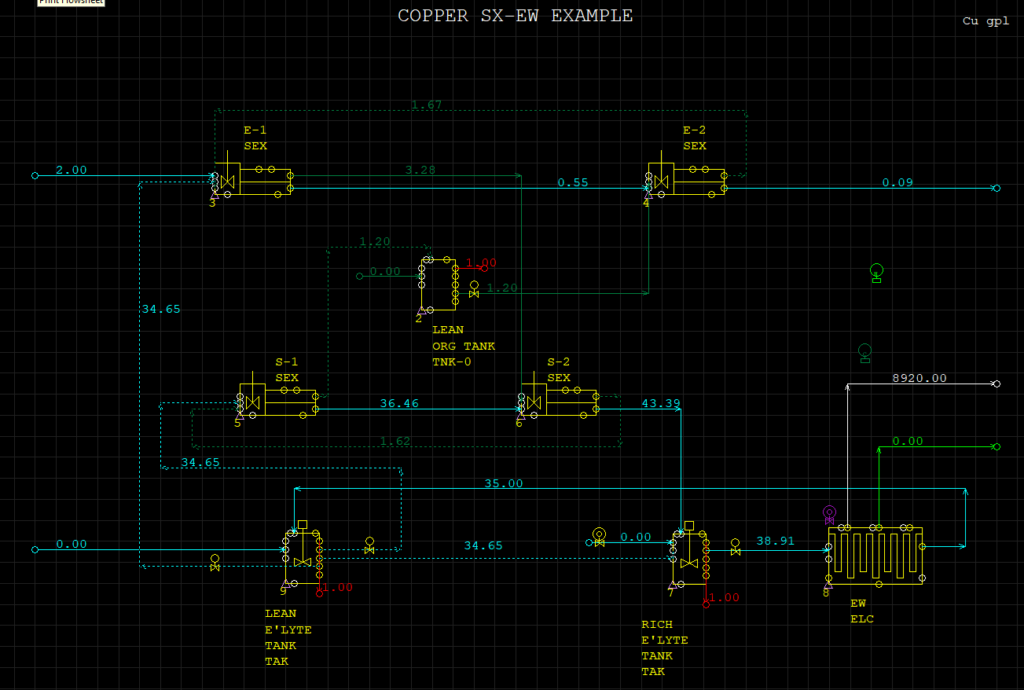

In the first illustration below, the crusher capacity and final particle size distributions are calculated in a comminution circuit. The second figure gives a flowsheet of a solvent extraction – electrowinning plant where the process efficiency is analysed as a function of consumption of organic solvent and acid .

InsPyro is your METSIM® agent in Europe. Contact us for a demonstration! We can also support you in building and understanding flowsheets. Our website will inform you on upcoming courses in METSIM®.

Next METSIM® webinar: 01/09/2021 at 10.00 (Brussels time).

Next METSIM® training: 06-09/09/2021

More information on the software can be found on www.metsim.com.