Fluid dynamics simulation

Gain insight into the flow or heat transfer behaviour of your process or design. InsPyro performs reliable CFD analysis to understand issues with the goal to find a suitable improved design, whether it is an HVAC system, a small machinery component, a settler, or a furnace layout.

Rely on InsPyro’s CFD specialists to efficiently model geometry, specify boundary conditions, run CFD simulations, interpret the results, and formulate practical recommendations.

Our specialists have a wide experience in CFD (Computational Fluid Dynamics) techniques including combustion, radiation, particle physics, multiphase flow, and aeroacoustics.

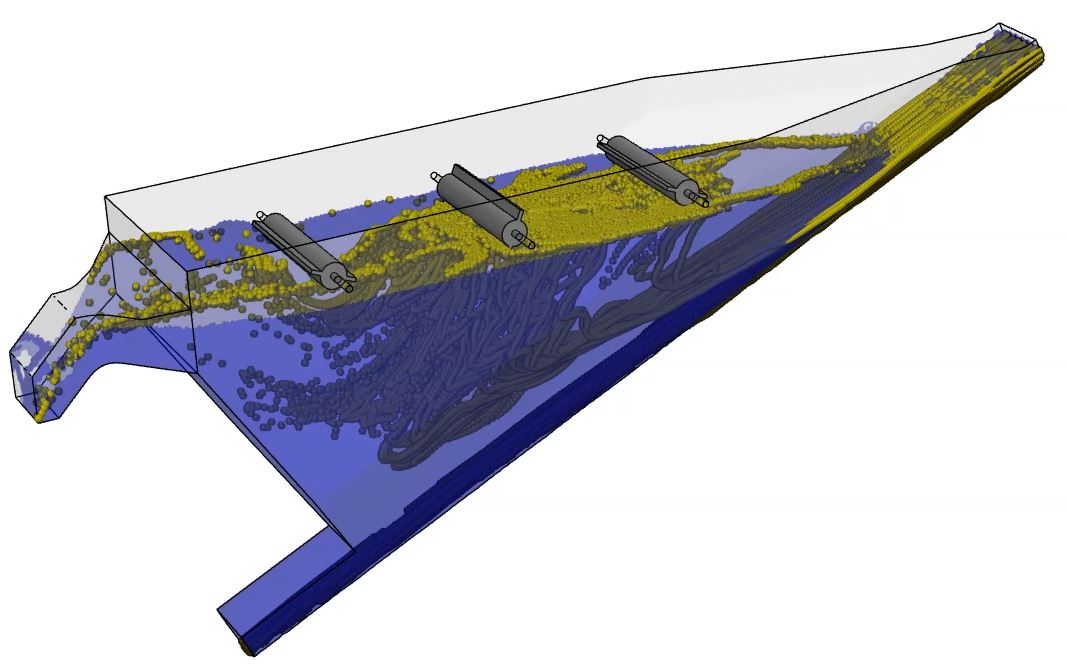

For particle physics, DEM (Discrete Element Method) can also be used. In this method, the behaviour of solid material is modelled by tracking large amounts of particles. The models can cover flow, mixing, heat transfer, breakup etc. of the particles of different shapes and sizes.

Our aim is to deliver a relevant and understandable answer to your question, without delay. Our customers most frequently chose the words Useful, Clear, Reliable, Flexible, and High quality to describe our services.

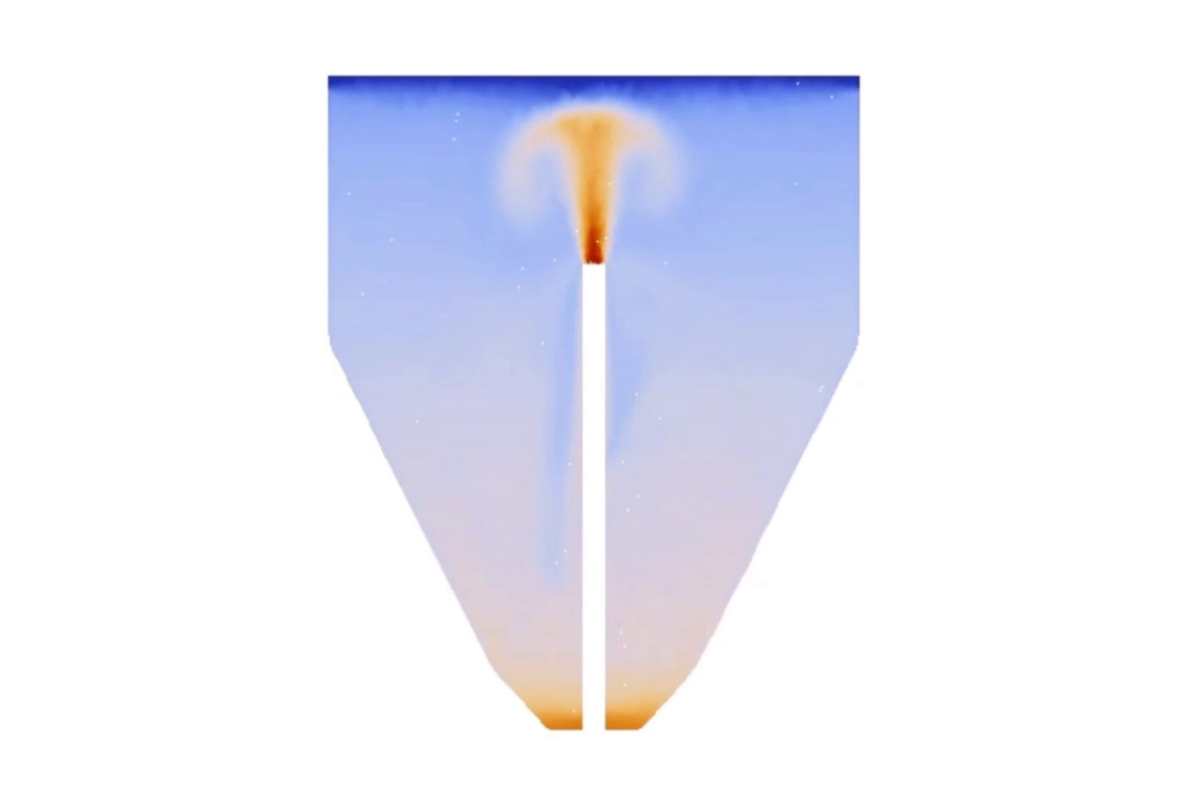

Case study: gas-fired furnace

We assisted several customers to improve the heat distribution or energy efficiency of their furnaces. CFD models help to eliminate hot spots, improve heat transfer, and reduce air entrainment.

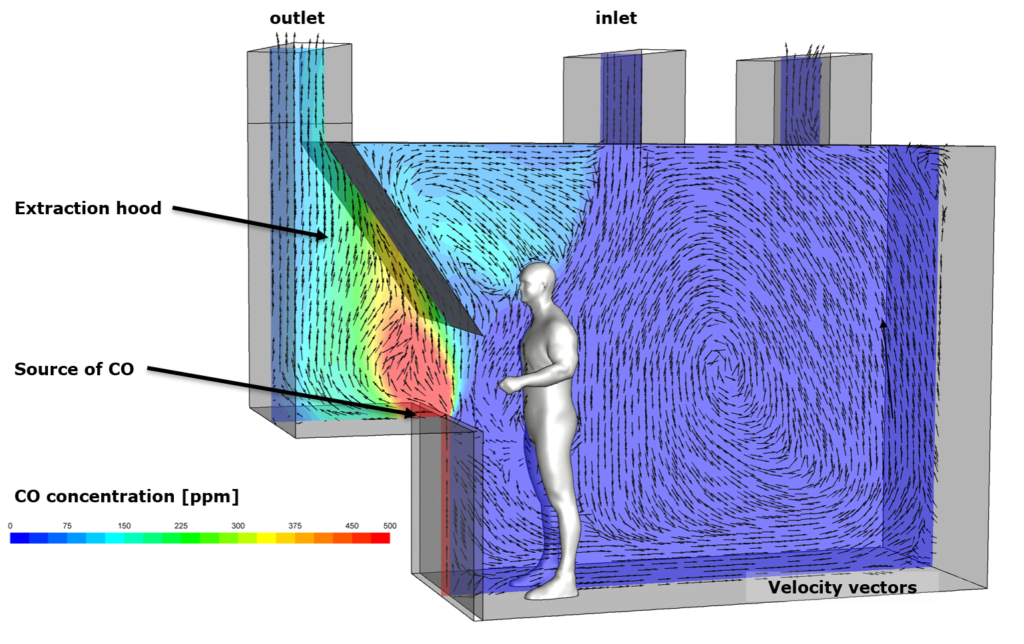

Case study: gas dispersion

When dealing with toxic gases, CFD provides details on flow pattern and concentration build-up in case of a leak. These insights can be used to position sensors smartly, and to be sure that a leak is detected quickly. Also, health risks can be quantified, and the effect of safety measures can be studied.

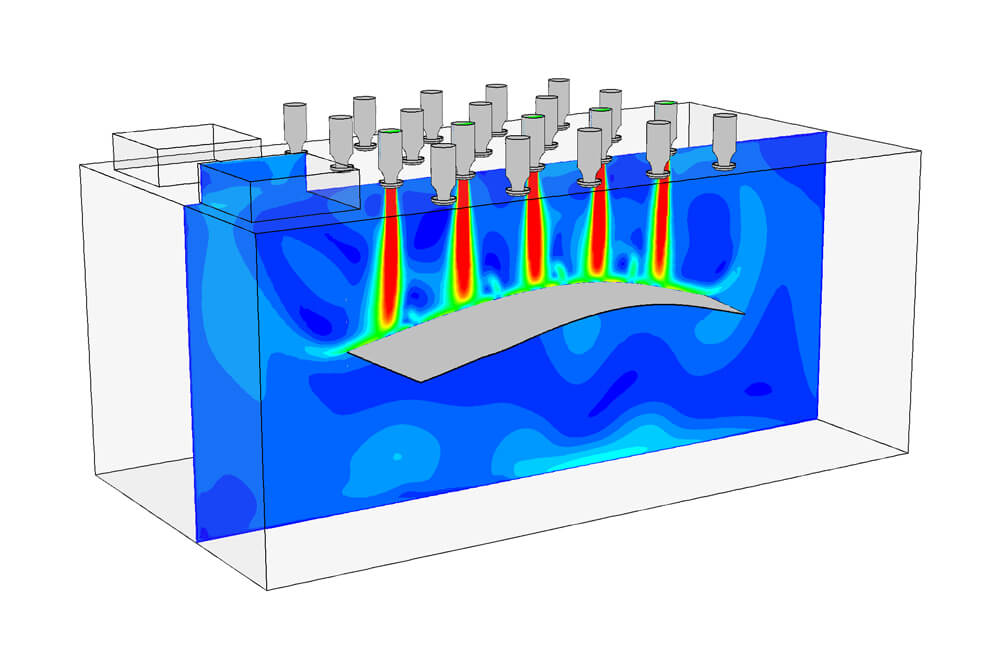

Case study: wastewater treatment plant

Settling, mixing and aeration are common issues in WWTP’s which may greatly benefit from a CFD analysis. This may be relevant for troubleshooting existing installations or optimizing new designs.

Case study: cooling of a cleaned part

Our customer, specialised in cleanroom technology, needed to guarantee a uniform temperature of cleaned parts entering the cleanroom. With CFD, we compared the heat transfer for different air inlet designs.

Case study: ventilation

Ventilation can save lives, but how can you be sure that enough air movement is provided to remove toxic or explosive gases or pathogens? Computational Fluid Dynamics (=CFD) calculates air flow and visualises potential health and safety hazards.

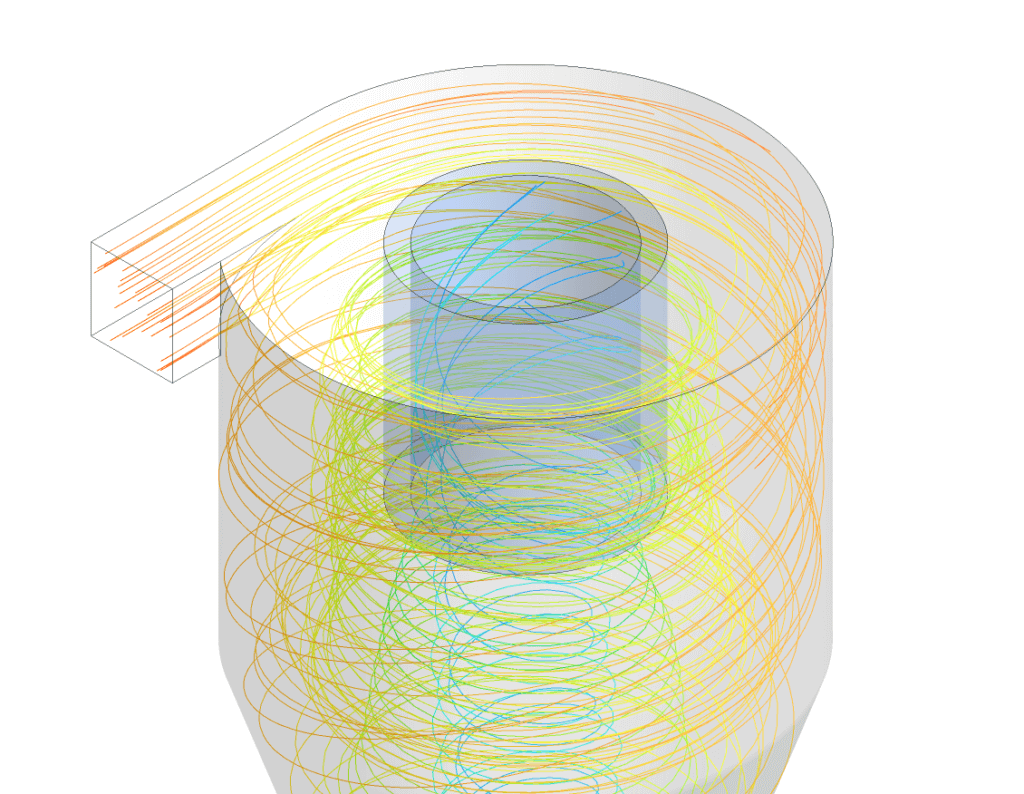

Case study: gas cyclone

To separate even the smallest contaminant particles from a gas or water stream, small optimizations to the cyclone design can make a big difference.

Read our application note on cyclone particle removal efficiency

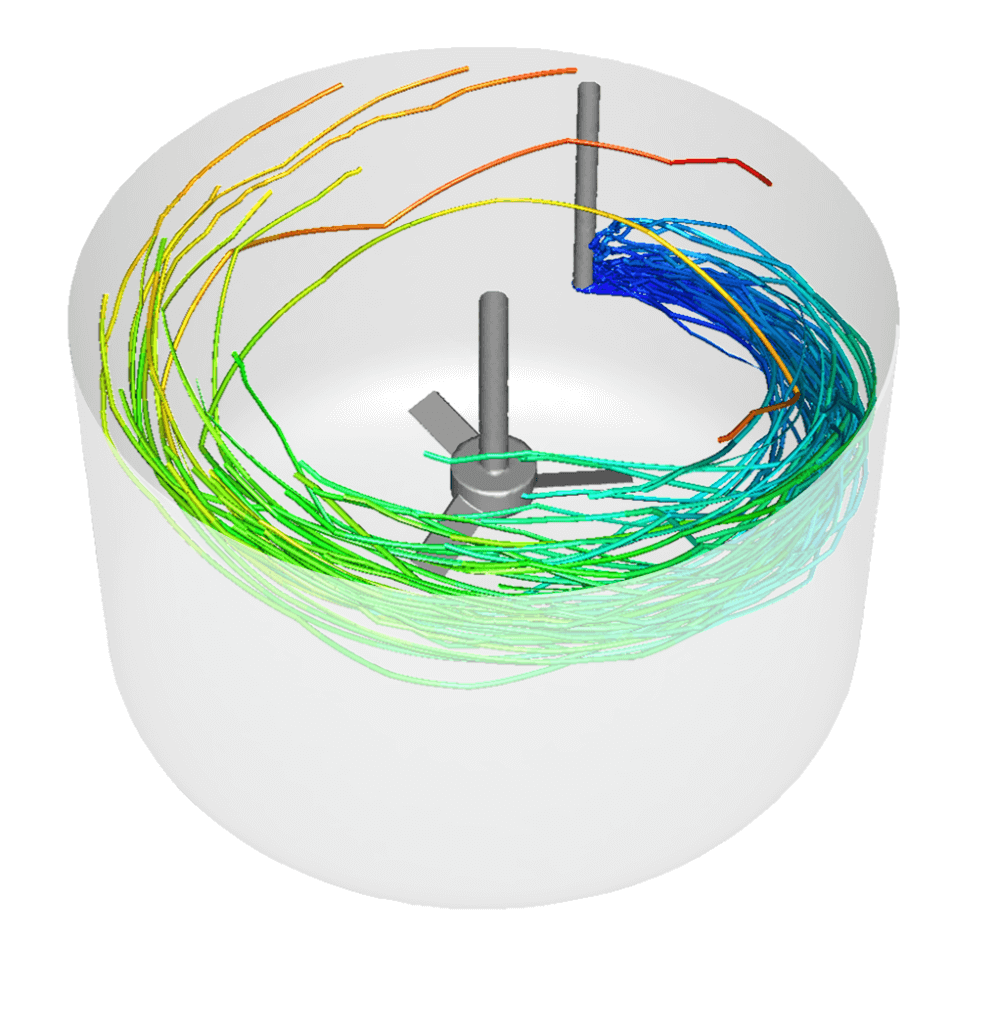

Case study: multiphase mixing

For optimizing mixing or increasing the residence time of the injected gases, whether in wastewater treatment or in liquid metal, CFD is an efficient design support tool.

Read our application note on redesigning a lead refinery stirrer

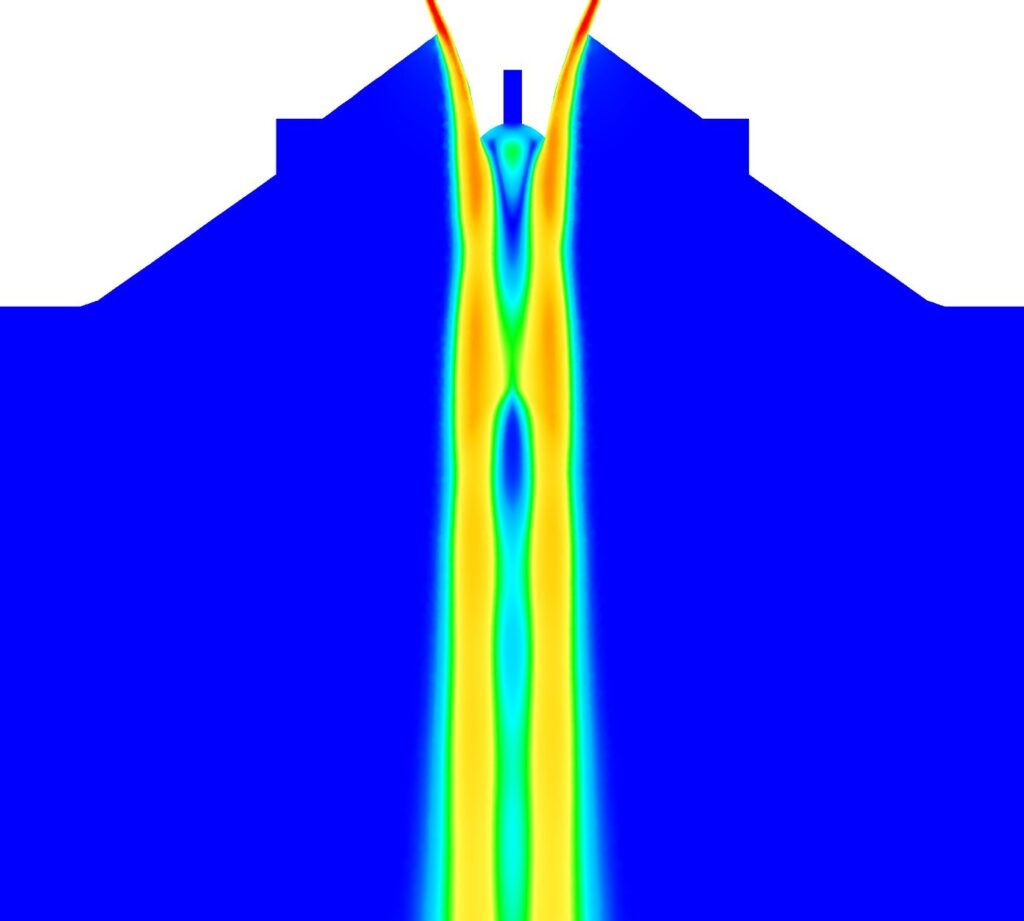

Case study: spray and atomization

Sprays and high-speed particle injections have an established role in various industries. However, adapting them to different scales and units needs to be tested thoroughly. CFD is a great tool to enhance this process while saving the cost and time of pilot tests.

Case study: gas injection into liquid material

Designing an optimal degasser is essential for removing unwanted dissolved gases, air bubbles, or volatile components during certain processes. CFD modeling helps tackle these challenges and allows for various testing scenarios.

Case study: a sink-float separator

Density-based separation is a common method for separating materials. By utilizing CFD modeling, different feed rates and separation efficiencies can be evaluated, along with design optimization.

InsPyro runs Ansys Fluent software to model, predict and analyse flow and heat transfer. Alternatives are CFX or OpenFOAM. Using these renowned simulation tools, our specialists reveal the hydrodynamics of gas flows, chemical aqueous or organic liquids, and even liquid metal or hot dust laden gases. Heat conduction, radiation, and convection models are included to study and optimize heat transfer problems.

Using the insight acquired, the process or design can be improved further to increase economics and establish a healthier working environment. As heat transfer is often a key driver in process capacity, improvements can have a large impact on profitability. Similarly, solving flow and pressure loss bottlenecks can allow for cost savings or capacity expansion.

CFD analysis can resolve a range of process issues:

- Improve mixing to avoid dead zones and increase reaction kinetics

- Modify hood and ventilation design to maximise emission removal, influencing worker hygiene

- Change burner or heater positions to optimise heat distribution, and thus thermal efficiency, wear, or energy consumption

DEM analysis can cover process topics such as:

- Improve mixing of solids, with different shapes and sizes

- Understand transport of the particles, e.g. understand the residence time distribution in a rotary kiln or (multiple) hearth furnace

- Improve heat transfer to bulk solids and ensure homogeneous temperatures

Thanks to their combined expertise in the applications as well as in the physical basis of CFD and DEM, InsPyro specialist consultants provide more valuable insight. They provide well-founded analysis results and actionable conclusions in the shortest time possible.

This information allows for efficiently resolving specific issues and realize performance improvements in your processes, or make quick changes to your product design without extensive testing iterations.

Reference customers for CFD

Hereaus Electro-Nite

3D Systems

Engitec

Aurubis

ABN

VITO

Nyrstar

Recytech